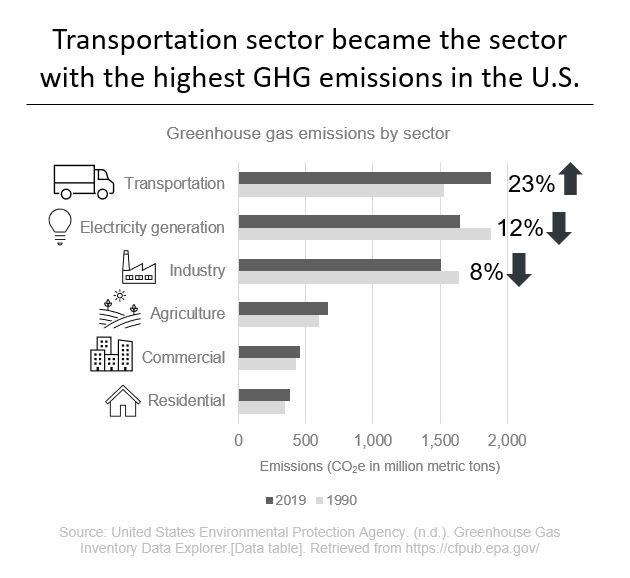

After decades of debate, last year’s COP26 Conference in Glasgow united the world in one truth: climate change is the existential crisis of our time. And we are at a critical moment in this fight; with data clearly illustrating a ceiling of 900 giga tons of CO2 to keep global warming below 2o Celsius1. Meanwhile, the transportation sector continues to be at center stage, becoming the biggest contributor to greenhouse gas (GHG) emissions in the United States, surpassing even electricity generation. But just as history has always been punctuated by innovation, we have the necessary solutions to reverse our path if we are brave enough to face the problem head on and act with decisive purpose.

Carbon is one of the most abundant elements in the universe and the epicenter of the climate crisis, constituting three quarters of GHGs. There is no doubt in the scientific community that man-made carbon emissions are pushing humanity towards a point of no return, but the sources of these emissions are still the subject of considerable finger pointing. When we pull back and try to see our changing world through a clear lens, a fundamental paradigm emerges that cannot be ignored if we are to combat climate change at the source: Growing economic prosperity is an impactful driver of rising carbon emissions.

As the global economy grew, we pulled more than a billion people out of extreme poverty and expanded the middle class. The Brookings Institute, for example, marked 2018 as the first year where over half of the world’s population lived in the middle class and rich households. This growing economic prosperity stimulated trade, infrastructure development, and industrial activity – and unfortunately, drove the growth in carbon emissions. This intrinsic link between prosperity and carbon emissions begs the question: can healthy economic growth and a healthy planet co-exist? Yes, investing in decarbonization is one of the most promising growth opportunities for our generation; and progress in it can make our society more prosperous and our planet healthier at the same time.

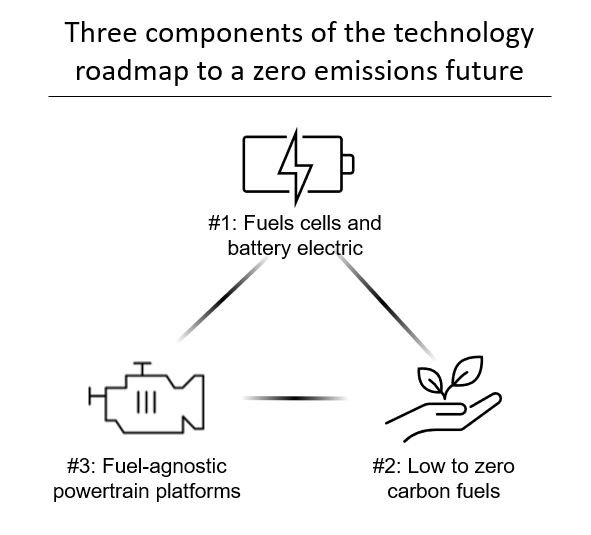

This journey to Destination Zero, which highlights Cummins’ journey towards eliminating carbon emissions, is rooted in a comprehensive technology roadmap for transportation and mobility with three primary components: Zero emissions technologies such as battery electric and fuel cell electric, low to zero carbon fuels, and fuel agnostic powertrain platforms as transition technologies.

No.1: Zero emission technologies such as battery electric and fuel cell electric

Today, battery electric and fuel cell electric solutions are economically and operationally viable for select commercial transportation use cases. These zero-carbon technologies are already helping with local emissions and air quality issues as they emit no carbon from a tank to wheel perspective. Moreover, when their energy source is green, for example renewable electricity used for battery electric buses, these technologies can offer zero carbon emissions from a well-to-wheel perspective. We already partner with school and transit bus manufacturers for all-electric applications, and there is even a passenger train in commercial operation that is powered by fuel-cell electric technology.

We have impressive technologies at our disposal, yet there are still many commercial transportation applications that face major roadblocks to electrification. Economic viability, mission accomplishment, and infrastructure support are the key factors behind these hard to electrify applications. One school of thought is to wait for battery-electric or fuel cell electric technologies to catch up to these applications, but we simply cannot afford to release more carbon emissions every day that we cannot take back. Every gram of carbon emitted will contribute to climate change. In the U.S. alone, medium and heavy-duty trucks emit over one million metric tons of CO2 every single day2. For these hard to electrify commercial transportation applications, there are options available today to significantly reduce or fully eliminate carbon emissions: low to zero carbon fuels.

No.2: Low to zero carbon fuels lower and eliminate carbon emissions on a well-to-wheel basis

Low to zero carbon fuels emit less carbon, on a well-to-wheel basis, than diesel fuel when used to produce power. I categorize these low to zero carbon fuels into four groups.

First is low-carbon fuels. These fuels still emit carbon when burned but emit less carbon than diesel fuel. Second is carbon neutral fuels. These fuels also emit carbon when burned, but the carbon emissions are fully offset by another activity. Third is zero carbon fuels. These fuels do not emit carbon at all when burned. For example, green hydrogen is a zero-carbon fuel. Fourth is carbon negative fuels. These are the fuels where the impact of the fuel generation and consumption results in a net reduction in GHG emissions.

From this crowded field of low to zero carbon fuels, few will be the most impactful: hydrogen, natural gas, and biodiesel. Beyond these three, synthetic fuels – also known as e-fuels, are an exciting additional technology that may emerge as a dominant factor in the future.

Hydrogen is an increasingly popular energy carrier. This is primarily because it is a zero-carbon fuel when produced using renewable energy sources like solar, wind and hydropower to electrolyze water. Hydrogen can fuel vehicles through an internal combustion engine or hydrogen fuel cell and deliver impressive reductions in carbon emissions. A model year 2027 Class 8 sleeper cab semi, powered by a hydrogen engine and fueled by green hydrogen, would save 1,437 metric tons of CO2 over its life versus its diesel-powered counterpart3. These are impressive environmental gains, but hydrogen faces two primary roadblocks today: infrastructure readiness and the abundant availability of green hydrogen – a zero carbon fuel well to wheel.

As opposed to hydrogen, natural gas is a fossil fuel, but it produces less carbon that other fossil fuels such as diesel. Natural gas also offers important emission reductions now as the infrastructure for zero carbon technologies continues to develop. In certain use cases, renewable natural gas (RNG) can be carbon negative, as well. For example, RNG produced from degradation of organic matter, that would otherwise be left to emit methane emissions, has negative carbon intensity. Meanwhile, there are two on-going debates around natural gas’ role in reducing carbon emissions. First, it is widely accepted that a portion of natural gas’ tail-pipe emissions gains is offset by methane leakages through pipelines. Second, the math behind RNG’s negative carbon intensity. It is important to recognize not all RNG has negative carbon intensity, and we should evaluate how the methane captured was originated and the efficiency of RNG transportation to determine whether the subsequent RNG usage results in a net reduction in GHG emissions.

Biodiesel is a renewable fuel produced primarily from fats and vegetable oils. The plants used as feedstock to produce biodiesel withdraw carbon from the atmosphere, and when biodiesel is burned, it returns the same carbon atoms back to the atmosphere; theoretically, this makes biodiesel carbon neutral4. Practically, the emissions generated while growing these crops and producing biodiesel also need to be considered. B20 is already in our lives today with many engines capable of running on it; the next step towards lowering emissions will be to have engines that can run on B40 and then on B100, pure biodiesel.

Synthetic fuels, or e-fuels, come in various forms; e-diesel and e-gasoline are the two that are more relevant for commercial transportation applications. These fuels can be produced using CO2 and green hydrogen; therefore, they are carbon-neutral, since they release the carbon that was originally used to create them back to the atmosphere. Moreover, they can also leverage our existing fueling infrastructure. Currently, there are two obstacles around these fuels: their high cost and limited availability.

Infrastructure readiness is a common obstacle for increased adoption of some low to zero carbon fuels. Meanwhile, there are commercial transportation applications that do not require an extensive network of fueling stations and other infrastructure. For example, fleets operating medium and heavy-duty trucks can create itineraries using a small number of fueling stations placed along fixed routes. This can then drive the needed infrastructure buildup.

Today, these low to zero carbon fuels are available for those looking to advance their decarbonization efforts. And their usage can be expanded with the help of a familiar technology: internal combustion engines – but with an innovative twist: fuel agnostic engine platforms. These platforms are the means to help us realize the benefits of low to zero carbon fuels.

No.3: Fuel-agnostic engine and powertrain platforms can expand the use of low to zero carbon fuels

Fuel agnostic engine platforms feature a series of engine versions that are derived from a common base engine. The bottom end of the engine looks the same, and unique cylinder heads are designed to accommodate a different low or zero carbon fuel. Each engine version operates using a specific type of fuel, including diesel, propane, natural gas, or hydrogen. These engines take advantage of existing technology and can reduce GHG emissions using low and zero carbon fuels. They have familiar operating practices, vehicle installation, and performance characteristics with today’s diesel engines. These fuel-agnostic platforms are ideal for use cases where battery-electric and fuel cell electric solutions are not yet financially or operationally feasible. This is an industry first of developing fuel agnostic internal combustion engines from the ground up. This is our effort to mix and match the right engines for the right applications as we move towards a zero emissions future.

It is also important to remember that these three components within the technology roadmap are not binary choices. You can combine battery electric solutions with fuel agnostic powertrain platforms to create hybrid solutions for the right use cases.

Climate change is the existential crisis of our time, and an increasing number of governments and companies around the world have already pledged to be carbon zero or negative. These solutions offer a viable path in this journey over the next couple of decades. But end users should not wait to take tangible steps in their journeys. Now is the time to decarbonize. Our planet cannot wait. And now, end users have the tools and innovations needed to charter their own unique paths to Destination Zero.

References:

1Intergovernmental Panel on Climate Change. (August 2021). Climate Change 2021, The Physical Science Basis [PDF file]. Retrieved from https://www.ipcc.ch

2United States Environmental Protection Agency. (December 2021). U.S. Transportation Sector Greenhouse Gas Emissions.[PDF file]. Retrieved from https://www.epa.gov/

3Analysis conducted using U.S. EPA's Greenhouse Gas Emissions Model (GEM) for Medium- and Heavy-Duty Vehicle Compliance. Assumed 19 tons payload, 120,000 thousand miles per year use. Retrieved from https://www.epa.gov/

4United States Energy Information Administration. (n.d.). Biofuels explained, Biomass-based diesel and the environment. [Web page]. Retrieved from https://www.eia.gov/